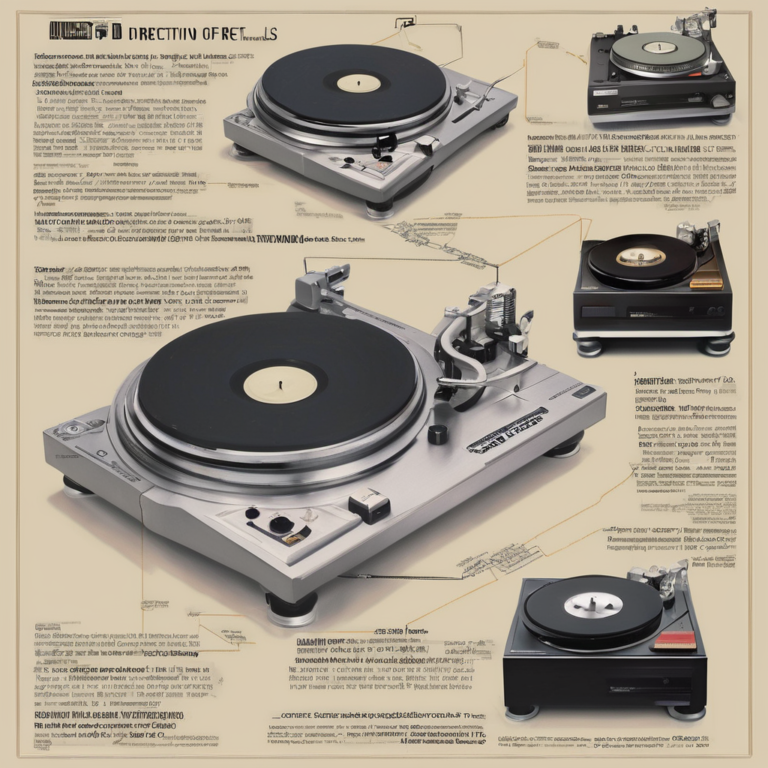

The Mechanics of Direct-Drive Turntables

If you’re a music aficionado like me, you’ll know that nothing beats the sound of vinyl. But to truly appreciate that unique sound, you need to understand how direct-drive turntables work. Despite the complexity, getting to grips with the mechanics can greatly enhance your listening experience. I’ve spent countless hours poring over spec sheets and I can tell you, it’s a game-changer.

Now, I get it. The terms and tech jargon can be intimidating. But don’t let this deter you. I promise, once you get the hang of it, you’ll see that it’s not as complicated as it first appears. In fact, understanding these terms can actually help you make better decisions when investing in your next turntable. Trust me, it’s worth the effort.

Basics of Turntables

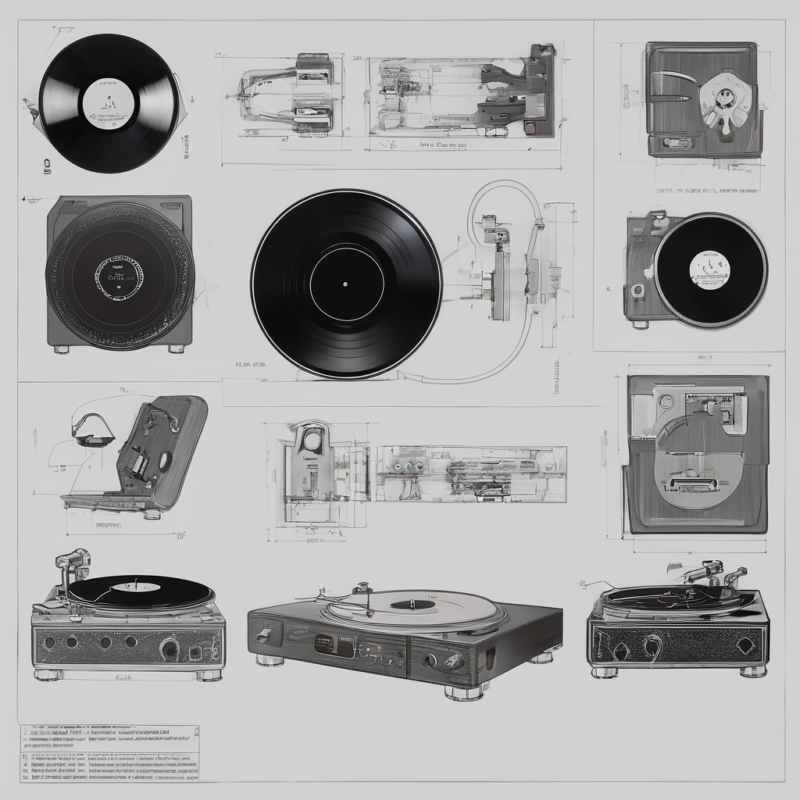

Taking a step further into the world of record spinning, let’s delve into the nuts and bolts of how these machines work. Essentially, the significant distinction between a belt drive and a direct drive unit lies in where the motor is located and how the platter is spun.

In a direct drive, the platter spins directly on the motor’s spindle, offering high torque and accurate rotation speed. This precision and the ability to start and stop rapidly make these models a favorite among DJs. However, without proper damping, this can lead to unwanted vibrations and potential distortion in sound quality.

On the other hand, in a belt drive model, the motor is off to the side, rotating the platter like a pulley. The rubber belt acts as a buffer, absorbing the motor’s vibrations before they can reach the stylus nestled in the record’s groove.

The cartridge, bearing, and spindle all play a part in maintaining sound quality. Though belt drive models require more precision in manufacturing, they generally offer superior damping and less distortion.

Why Choose Direct Drive?

For starters, the quick start-up speed of these machines is a major pull. They’re up and running in no time, thanks to the high thrust they possess. Anyone who’s in a hurry to kick off their music will appreciate this feature.

Moreover, they’re less prone to the effects of external forces. This makes them a reliable choice for those who want to ensure their music session goes uninterrupted. This durability and resilience make them a favorite of disc jockeys, who also love the ease of manually rewinding records with them.

However, on the flip side, there’s a likelihood of audio interference. This results from the direct transmission of tremors from the machine’s heart to the main operational surface, which might lead to potential audio deviations.

Belt Drive vs. Direct Drive

In the world of vinyl record players, the debate between belt-drive and direct-drive turntables continues to be a topic of discussion among audiophiles. The key difference lies in the manner in which these two types of turntables transfer the motor’s rotational energy to the platter where the record is placed.

Belt drive turntables utilize an elastic belt to connect the motor to the platter, acting as a buffer that reduces the potential for motor noise and vibration to reach the stylus. On the other hand, direct-drive turntables feature a design where the motor is directly connected to the platter. This direct connection can offer more consistent speeds, greater torque, and faster start and stop times.

However, it may also leave the stylus more susceptible to mechanical noise and vibrations from the motor. Each design has its own set of advantages and drawbacks, making the choice largely dependent on the specific needs and preferences of the user.

Maintenance and Upgrades

Proper maintenance and upgrades of direct-drive turntables are imperative to ensure optimal performance and longevity. Here, we will outline some key considerations and steps to follow.

Maintenance primarily involves routine cleaning and careful handling. Dust and dirt can interfere with the turntable’s functionality, so it is recommended to use a carbon fiber brush to clean the stylus and a record brush to clean your vinyl records. Additionally, the platter should be cleaned regularly with a soft, lint-free cloth.

When handling your turntable, avoid touching the stylus needle to prevent oil contamination, which can degrade the sound quality. Also, ensure that the turntable is positioned on a stable surface to avoid unnecessary vibrations that could affect playback.

In terms of upgrades, the cartridge, stylus, and phono preamp are the most common components to consider. Upgrading the cartridge or stylus can significantly improve the sound quality as these are the parts that come into direct contact with your records. Investing in a high-quality phono preamp can also enhance audio output.

When performing any upgrades, remember that the components should be compatible with your specific turntable model. Improperly installed upgrades can damage your turntable or degrade its performance.

Lastly, it is advisable to have your turntable serviced by a professional if you notice any persistent issues or if it’s been a long period since its last servicing. Regular inspections can help identify potential problems before they escalate, ensuring that your turntable maintains its top performance over time.

In conclusion, regular maintenance and thoughtful upgrades can significantly enhance the performance and lifespan of your direct-drive turntable. By investing time and effort in these areas, you can ensure that your turntable continues to provide high-quality audio for years to come.

Direct-Drive Turntables: A Listener’s Perspective

Audiophiles often have a fascination with the science behind sound. For them, listening to music isn’t just about the melody; it’s about the quality of sound, the nuances, and how the music is delivered. Among the different types of audio equipment, turntables, specifically direct-drive turntables, have garnered substantial attention.

From a listener’s perspective, the direct-drive turntable is an intriguing piece of audio technology. The device’s unique design allows the platter, where the vinyl record is placed, to be driven directly by a motor. This direct engagement eliminates any potential slippage or speed inconsistencies that could arise from a belt-driven system, thereby ensuring a more stable rotation and, subsequently, a more precise playback speed.

While the technical aspects of direct-drive turntables can be intricate, listeners primarily focus on the resulting sound quality. The direct-drive system provides a consistent, steady spin, which is vital for maintaining pitch accuracy. This precision leads to a clear, high-fidelity sound that is often preferred by professional DJs and audio enthusiasts.

Moreover, some listeners appreciate the quick start-up speed and stronger torque of direct-drive turntables, characteristics that not only enhance the listening experience but also provide the ability to manipulate the record, a feature favored by DJs for beat mixing and scratching.

FAQs

What is the main difference between direct-drive and belt-drive turntables?

The crux of the difference lies in the way the circular platform (where your records sit) is powered. In direct-drive models, the power source is connected directly to the spinning base. On the other hand, belt-driven models have the power source located off to the side, with a belt serving as the link between the two. This fundamental difference impacts not only the operation of your record player but also the listening experience it offers.

Why are direct-drive turntables preferred by DJs?

There are several reasons. First, these master beat matches appreciate the immediate start-and-stop feature inherent to these decks, which leverages the power transmission mechanism linked directly to the record-playing platform. This enables quick reactions to the crowd’s vibe – a critical skill in their trade. Second, a stronger driving force allows for easy manipulation of the record’s pace – think scratching or back-cueing – without worrying about the deck slowing down.

Are there any performance differences between the two types of turntables?

Yes, there are notable performance differences between direct-drive and belt-drive turntables. Direct-drive turntables tend to have stronger torque and quicker start-up times, making them preferred by DJs for their reliability and for scratching records.

On the other hand, belt-drive turntables are favored by audiophiles because the belt absorbs shock and reduces vibration, providing superior sound quality. However, the belt may need to be replaced over time. Ultimately, the choice between the two largely depends on the user’s specific needs and preferences.

Conclusion

In conclusion, the choice between distinct types of record players depends greatly on personal preferences and usage. From a user’s point of view, the mechanics behind these devices could be the deciding factor. Inherently, upkeep and optimization also play a significant role in the overall experience.

To sum up, it’s crucial to familiarize oneself with the ins and outs of these machines. Each type has its own merits and drawbacks which require careful consideration. But, at the end of the day, it’s all about enjoying the music, isn’t it?

Further reading: How to Buy a Record Player

Our Mission: At AudioInspects, we are dedicated to providing the most comprehensive and authentic reviews of audio equipment on the market. We conduct independent testing and research of products, so you can make an informed decision before making a purchase. Our mission is to help you find the best audio equipment to improve your listening experience. So trust us to deliver the most reliable recommendations and advice.

Disclosure: When you do decide to make a purchase through our links, please note that we may earn a commission, but this does not affect the honesty of our reviews. You can read our affiliate disclosure in our Disclosure.